Sandwich Panel Prices

Sandwich Panel Prices, the demand and material prices in the sector varies according to the prices. Prices as of 2025, used steel, number platequality and thickness. Especially 5cmAnd 10cmThicknesses are among the most preferred models.

Sandwich panel prices can be observed on Istanbul, Dilovası, Gebze and Anatolian Side. In general kgAnd tonThe prices determined as varies depending on the size of the construction projects in these regions and the materials used.

The market averages for 2025 are determined by calculating the area (m2). For example, none whiteAnd colourfulThere are changes between the prices of sandwich panels. Another important issue to be considered when buying is the densities used. DensitiesOffering different options in terms of producers, providing the most appropriate solution for the needs of your project.

Moreover, PricesOther factors that affect include material supply, shipping expenses and assembly services. All these factors can significantly affect the overall budget of each project. Therefore, it is useful to consider all these elements when planning budget in your sandwich panel recruitment.

What are the differences in the Cold Room Sandwich Panel and Roof Sandwich Panel?

Cold room sandwich panels and roof sandwich panels are two different types of sandwich panels used in various building applications. The main purpose of these panels is to provide insulation; However, there are some significant differences in terms of usage areas and technical characteristics.

| Feature | Cold room sandwich panel | Roof sandwich panel |

|---|---|---|

| Usage area | Cold Room Applications (Food Storage, Medicine, etc.) | Roofing and insulation |

| Thermal Insulation Performance | High insulation values (usually polyurethane fill) | Good insulation but not as high as cold room panels |

| Thickness options | 5cm, 10cm and more | Various thickness options available |

| Material | Polyurethane filling with a steel plate | Usually steel plate coating |

| Color Options | White, colorful | White, colorful |

| Price range | Higher than other panels (especially depending on density and thickness) | In general, more affordable |

Sandwich panelvarieties, their own technical specifications and application areas attract attention. Cold room panels, higher insulationWhile serving special usage areas by offering values, the roof panels usually serve as insulation and coating at the top of the buildings. At this point, Sandwich Panel PricesIt varies depending on the type, thickness and material used.

Sandwich Panel Types (facade, roof, cold room,…)

Sandwich panels have different types according to their structural properties and application areas. At the beginning of these species front, roofAnd cold roomPanels come. Each species is designed according to certain needs and offers different functions in construction projects.

- Front sandwich panels:Usually used on outer walls. They stand out with their aesthetic appearance and energy efficiency. It is durable with its steel structure and adds richness to architectural projects with its various color options.

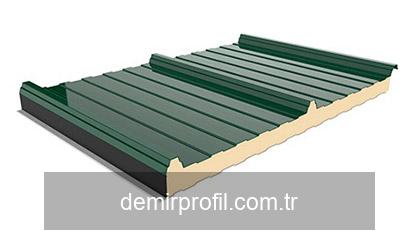

- Roof sandwich panels:These panels used on roofs have high insulation properties. They are resistant to weather conditions such as rain and snow. RoofThe panels are usually offered with 5cm and 10cm thickness options.

- Cold Room Sandwich Panels:It is used in areas such as food storage or cold storage. High densitiesThanks to the heat loss to the minimum. With reasonable prices Istanbul, GebzeAnd DilovasiThey are often preferred in industrial zones such as.

While choosing between these panels, Menstrual PricesIt is important to consider factors such as thickness and density. The prices of various models between these species may vary according to the materials and measurements used. Different modelsAnd PricesIt is possible to find the most suitable option by researching.

Single Sandwich Panel Single Floor Trapezes Differences

There are significant differences between sandwich panel and one -layer trapezoidal. Both construction materials have different usage areas and advantages. The main differences between these two materials:

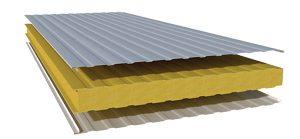

- Structure and Design:Sandwich panel is a building material with insulation material between two metal surfaces. Single layer trapeze consists of only flat or trapezoidal metal plates.

- Heat insulation:Sandwich panels offer high thermal insulation thanks to the thickness of the insulation material. In this way, they are more effective in saving energy. One layer of trapezes do not have insulation properties.

- Uses:Sandwich panels are generally preferred in areas such as cold rooms, roofing and facade coating. Single layer trapezes are often used in areas that require less insulation, for example in roofing.

- Weight and durability:Sandwich panels offer high weight resistance to low weight thanks to the design of their structures. Single layers of trapezes can be more severe and show less durability.

- Cost:In general, the sandwich panel prices can be higher depending on the materials and insulation properties used; One -layer trapeze stands out as a more economical option.

Considering these differences, the most appropriate choice should be made according to the needs and budget of your project. Both materials have their own advantages and successful results are obtained in projects when used correctly.

Sandwich Panel Thicknesses and Weight Table

The thickness and weight of the sandwich panels varies according to the usage areas and the materials made. Below, various sandwich panelThe general information about their thickness and the table of gravity. The values in this table, especially priceIt can provide important information during the selection of panels to be used during research or in projects.

| Thickness (cm) | Weight (kg/m²) | Density (kg/m³) |

|---|---|---|

| 5 | 10 | 40 |

| 10 | 15 | 50 |

| 15 | 20 | 60 |

| 20 | 25 | 80 |

The values in this table are in regions such as Istanbul, Dilovası and Gebze Sandwich Panel Menstrual Pricescan create the reference point for. As the thickness of the panels increases, the prices increase. Moreover, steelor polyurethaneThe use of materials has a significant effect on the price of the panels.

Different modelsAnd color alternatives can also affect your choice. In your projects sandwich panelWhen using it, it is very important to choose the thickness and weight that suits your needs.

What are the differences in the Cold Room Sandwich Panel and Roof Sandwich Panel?

Cold Room Sandwich Panel and Roof Sandwich Panel are two important types of panels used for many different purposes in the building industry. However, there are some significant differences between these two panels.

Cold room sandwich panels, usually Cold Storage Areas, Food Processing FacilitiesAnd cold storage warehousesused in areas such as. These panels are specially designed to ensure energy efficiency at low temperatures and usually polyurethaneor EPS(expanded polystyrene).

On the other hand, roof sandwich panels are preferred to cover the upper part of the structures. These panels are widely used in roof making thanks to the load -bearing capacity of the waterproof feature. Roof sandwich panels usually steelor aluminumIt is produced with durable materials and is available in various thicknesses.

In addition, cold room panels are usually made of thicker and dense materials, while the roof panels can be designed in lighter and thin structures. Because, thicknessAnd densitiesThere is also a difference in terms of. The thickness of cold room panels is usually 10 cm, 5 cmRoof panels may have more variable thicknesses.

In terms of price, both panels Menstrual PricesAnd M2 Pricesmay also vary. Istanbul, Gebze, DilovasiThe prices of these panels in such regions differ and it is important to consider these factors when choosing.

There are significant differences between the use areas, material structure and physical properties between the cold room sandwich panel and roof sandwich panel. These differences play a critical role in determining which panel is used.

How to install the roof sandwich panel?

Roof sandwich panelInstallation is an important process that requires careful planning and appropriate equipment. Let’s examine the assembly steps step by step:

- PREPARATION STAGE:First of all, it is important to clean the area to be installed and to take the necessary safety measures. Pay attention to the robustness of the roof structure and all required for assembly materials(screws, support elements, etc.) should be provided.

- Placing the first panel:Roof sandwich panelFirst, it is placed on the roof shelves. The panel should be assembled at a correct angle and carefully aligned to adapt to each other.

- Squeeze the assembly screws:After the first panel is placed, appropriate screwsshould be squeezed using. The corners of each panel and the support points in the middle should be considered.

- Adding the second panel:After the installation of the first panel is completed, the second panel is placed in the same way and in accordance with the junction points with the first panel screwsshould be fixed with.

- Monitoring and Control Stage:Once all panels have been placed, the connections of the panels, the tightness of the screws and the slope of the roof should be carefully reviewed to check the robustness of the assembly.

- Ensuring waterproofing:Roof sandwich panelWaterproofing applications should be performed after assembly. Using water -resistant materials, it is important to provide sealing.

Correct implementation of these stages, roof sandwich panel pricesIt contributes to the acquisition of a long -lasting and durable structure in proportion to. Especially Istanbul, Gebze, DilovasiAnd Anatolian sideIn such regions, it may be advantageous to do price research before receiving assembly service.

What are the densities of Sanwiç Panel Polyurethane?

Sandwich panels are structural elements commonly used in the construction sector and often come to the fore with their high insulation properties. Polyurethane densities of these panels, both Sandal Panel PricesIt has a significant impact on its general performance. Polyurethane is the thermal insulation material used in the interior of the sandwich panel and can be produced in different densities.

The polyurethane density indicates the weight of the material in kilograms in 1 m³. Generally in sandwich panels of 5 cm and 10 cm thickness, the densities vary between 30 kg/m³ and 40 kg/m³. These densities affect the thermal insulation of the panel and also play a decisive role on the cost. Sandwich panels with high density often offer better insulation features, while prices vary accordingly.

In addition, these densities affect the durability and longevity of sandwich panels. Steel, number plateAnd modelsThe polyurethane density with it makes it easier for users to choose according to their needs. Especially Istanbul, Dilovasi, GebzeAnd Anatolian sideMany different options are offered for the needs of the construction sector in such places.

sandwich panel polyurethane densities, both PricesIt is also an important factor to consider in terms of performance. For this reason, the determination of the intensity in panel purchase is of great importance for the right choice.

Best suitable sandwich panel prices (m2)

Sandwich Panel PricesIn general, it varies depending on many factors. Prices differ depending on the quality, panel thickness, density of the material used and in which region to be made. Especially M2In sales made on the basis, steelAnd number plateQuality is of great importance.

Best suitable for 2025 Sandwich Panel PricesThe following table is given. These prices may vary according to the region and the supplier:

| Thickness (cm) | DENSITY (KG/M3) | Price (TL/M2) |

|---|---|---|

| 5 | 40 | 150 |

| 10 | 60 | 200 |

| 12 | 80 | 250 |

Prices in regions such as Istanbul, Dilovası, Gebze and Anatolian Side, tonAnd piecemay vary in the basis. Therefore, it is important to investigate regional prices before purchasing. If different modelsAnd colourfulIf you are evaluating alternatives, prices may vary accordingly.

Remember, an affordable sandwich panelIt would be very useful to conduct a supplier research and compare different offers to get.

Frequently asked questions

What is a sandwich panel?

Sandwich panel is a type of panel consisting of an inner filling material placed between the two outer surfaces and providing usually structural and insulation properties.

What factors depend on sandwich panel prices?

Sandwich panel prices vary depending on factors such as thickness, material type, production process, dimensions and order quantity.

What should be considered when buying a sandwich panel?

When buying quality, insulation properties, warranty time and the reliability of the manufacturer’s reliability should be considered.

In which areas of the sandwich panel is common?

Sandwich panels are generally used in industrial structures, cold warehouses, office buildings and housing projects.

What are the economic factors affected by sandwich panel prices?

Economic factors such as market demand, raw material prices, exchange rates and production costs affect sandwich panel prices.

What are the advantages of collective purchase when buying sandwich panels?

When collective purchase is made, discounts are usually provided, low cost and convenience in the supply process.

How to provide energy efficiency in sandwich panels?

Correct thickness and proper material selection, energy efficiency can be achieved with appropriate insulation; The assembly quality is also important.