Profile Laser Cutting Prices (Sample Price Table by Thickness)

Profile Laser Cutting Pricesvaries according to various thickness and sizes. Because, thicknessAnd sizeFactors such as are among the important elements affecting the total cost. Below is a sample price table according to different thicknesses:

| Thickness (mm) | Price (TL/kg) | Weight (kg/m) |

|---|---|---|

| 1 | 12.00 | 1.5 |

| 2 | 14.00 | 3.0 |

| 3 | 16.00 | 4.5 |

| 5 | 18.00 | 7.5 |

| 8 | 20.00 | 12.0 |

These prices, steelValid for profile laser cutting operations, IstanbulAnd Anatolian sideIt may vary according to markets in such regions. Moreover, wholesaleor retailPrice difference may occur in purchases.

The cut price of each profile is the complexity of the design, dimensionsAnd diameterIt will also be affected by variables such as. Therefore, it is best to contact manufacturers or suppliers to get net price information in special projects.

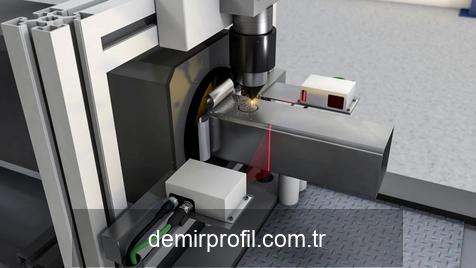

3D profile laser cutting

3D Profile Laser Cuttingis a common method of frequently in industrial applications. This cutting technique makes it possible to cut metal and other materials in three -dimensional ways. 3D cuts are generally used for prototype production, machine parts and special design products. Such cutting allows the creation of complex geometric forms and offers design flexibility.

3D Profile Laser Cutting PricesIt varies according to factors such as material, cutting dimensions, thickness and complexity of design. For example, different thicknessAnd coveringOptions are important elements that affect cutting prices. In addition, the speed of the production process and the update of the technology used play a role on costs.

In the pipe section, diameterAnd lengthConsidering the criteria such as. At this point, 3D profile laser cuttingThanks to it, the production of much more complicated structures becomes possible. WeightAnd the sizes are other elements that should be taken into consideration in these sections.

Profile Laser Cutting Prices, both the production process and the quality of cutting changes continuously. Therefore, it is important to consider all these factors when making cost calculations.

Profile Laser Cutting Sizes

Profile laser cutting operations, used dimensions, thickness, diameterAnd lengthIt is priced depending on factors such as. Especially steelmaterials like weightAnd strengthplays an important role in determining prices. For wholesale or retail shopping Profile Laser Cutting Pricesvaries.

In general, some standard sizes are as follows:

- Pipe sizes: Available in various sizes from 20 × 20 mm to 300 × 300 mm.

- Rectangular profile sizes: 20 × 40 mm, 30 × 50 mm, 40 × 80 mm offers a wide option.

- U profiles: It can rise from 40 × 40 mm to 100 × 100 mm.

In addition to the size used during cutting operations, thicknessIt also affects material properties and cutting quality. Different thicknessWith the options, customized cutting can be made for the project. This is the usage area of the product and the expected resistancemay vary according to the level.

Especially IstanbulAnd Anatolian sidecompanies in different companies are different for the needs of the customers to profilesfast and quality laser cuttingoffers services.

Profile laser cutting calculation

One of the most important factors affecting profile laser cutting prices, thickness, size, diameterAnd lengthlike measurements. Profile laser cut prices, depending on the properties of the material to be cut and the technologies to be used in the cutting process. You can follow the steps below to calculate the cutting cost:

- Material selection:Decide which material to cut. Steel, aluminum or other types of materials will affect prices.

- Thickness determination:The material to be used thicknessclarify. In general, as the thickness of the cut price increases, the cost increases.

- Size and sizes:The pieces to be cut their sizesAnd dimensionsIdentify. Different sizes affect the laser cutting process and therefore the price.

- Weight Calculation:The part of the part to be cut weightIdentify. Weight affects pricing depending on the amount of material. Formula for weight calculation: Weight (kg) = volume (m³) x density (kg/m³).

- Number of pieces:Determine how many parts you need. Discounts are usually applied for wholesale purchases.

The following tableshow profile laser cutting prices and thickness ranges for some types of materials:

| Material type | Thickness (mm) | Price (₺/mt) |

|---|---|---|

| Steel | 1-3 | 150 |

| Steel | 4-6 | 200 |

| Aluminum | 1-3 | 180 |

| Aluminum | 4-6 | 250 |

These calculation steps and tables, Profile Laser Cutting PricesIt will help you provide a better understanding about it. Always, it is useful to contact your manufacturer or cutting service provider for correct pricing.

Profile Laser Cutting Places

Profile Laser Cuttingis used in many different fields in the industry. These usage areas vary according to material types and size. Below are some places and sectors in which this technology is widely used:

- Construction sector: It is often preferred in cutting operations of steel structure elements. Especially Profile Laser Cutting Pricesoffers cost -effective solutions in terms of.

- Automotive Industry: Used in applications that require precise cutting in the production of vehicle parts.

- Machinery Manufacturing: It is an ideal method for the production of machine parts and equipment.

- Furniture sector: Used in the cutting of decorative metal parts and furniture skeletons.

- Advertising and Communication: Laser cutting technology is preferred in the production of metal signs and various advertising panels.

- Metal industry: It is a common method for the cutting of metal parts of different thickness and sizes.

- Art and Design: Laser cutting is preferred for original cutting techniques in artistic projects and personal designs.

These usage areas, Profile Laser Cutting PricesAnd thickness, lengthmay vary depending on parameters such as. Therefore, it is recommended to contact experts to find the right solution to your project requirements.

Profile Laser Cutting Min and Max Thicknesses

In profile laser cutting processes, the thickness of the material used is of great importance. Profile Laser Cutting Pricesdepends on thickness. Therefore, determination of the correct thickness is a critical factor for both cost and quality. Generally, the minimum and maximum thickness values in profile laser cutting applications are as follows:

| Material type | Min thickness (mm) | Max thickness (mm) |

|---|---|---|

| Steel | 0.5 | 20 |

| Aluminum | 0.5 | 15 |

| Stainless steel | 0.5 | 12 |

These thickness ranges may vary depending on the capacity of laser cutting technology and the properties of the machine used. In profile laser cutting applications, compliance with these thickness ranges optimize cutting quality and material resistance. Also, before the application material weight, measurementAnd lengthIt is recommended to consider the criteria such as.

Which thickness to use, pricedirectly affects. For example, as subtlety or thickness increases, Profile Laser Cutting Pricesis also rising. Therefore, it is important to plan the choice of thickness and materials that are suitable for the needs of your project.

Profile laser cutting types

Profile laser cutting varies according to different types of materials and cutting methods. These varieties, Profile Laser Cutting PricesIt also has an effect on it. Here are the most common profile laser cutting types:

- Steel Profile Laser Cutting:Steel profiles, which are widely used in construction and automotive sector, provide high strength and quality cuts.

- Aluminum profile laser cutting:Ideal for light structures, weightprovides advantage in terms of. Aluminum profiles usually MTIt is cut by measured in terms of.

- Stainless Steel Profile Laser Cutting:Stainless steel profiles, especially for use in the food and chemical sector, are high thicknessAnd resistancepresents.

- Copper profile laser cutting:Copper profiles with high electrical conductivity are preferred in special applications.

- Plastic profile laser cutting:It is used for light structures and is generally preferred for decorative purposes. Different measurementAnd dimensionsOptions are available.

Each type of profile, load to be moved, lengthAnd thicknessIt has different pricing according to factors such as. Profile Laser Cutting Pricesmay vary depending on the characteristics of these varieties.

Required size, pieceand other features, taking into account the most appropriate priceIt is possible to determine. On Istanbul and Anatolian Side; It is offered to customers with wholesale or retail sales options.

Profile Laser Cutting Features

Profile laser cutting offers many advantages as one of the modern metal processing methods. The quality of the parts cut by this method is on thickness, featuresand varies according to the type of material used. Some of the most prominent features of profile laser cutting process are:

- Cutting sensitivity:Laser cutting has the capacity to make smooth and clear cuts with high sensitivity. In this way, the necessary tolerances can be obtained.

- Minimum material loss:Profile laser cutting provides less waste of material than old cutting methods. This means a more economical production process.

- Different Types of Materials:Steel, aluminum, stainless steel, such as the ability to process on various materials, this method makes the versatile.

- Detailed design possibilities:Complex designs and details can be easily applied with laser cutting. This is a great advantage for industrial designs.

- High transaction speed:Laser cutting machines can cut quickly. This contributes to the acceleration of the production process.

- Risk of fire and flame:Laser cutting carries a lower risk of fire compared to other cutting methods, which provides a safe production process.

Profile laser cut prices, as well as these features measurement, thickness, diameterAnd lengthIt may vary depending on factors such as. Therefore, it is important to find the best price according to project -specific requirements.

3 axis laser cutting cost calculation

3 axis laser cutting is widely used in industrial sectors because it is a very sensitive and fast cutting method. This method, Profile Laser Cutting PricesIt is one of the important parameters that have an effect on it. Main factors affecting cutting costs include material thickness, cutting size and total workpiece weightvalues.

Elements to be considered for the cost calculation:

- Material Type:The prices of different materials such as steel and aluminum vary.

- Thickness:The thickness of the material to be cut can increase the cost by affecting the amount of energy used.

- Length and Size:The dimensions of the parts to be cut are another factor that directly affects the processing time and thus cost.

- Piece:If a large amount of cuts are to be made, usually in bulk orders wholesalePricing advantage can be provided.

The following table contains some assumptions for a general cost calculation.

| Thickness (mm) | Weight (kg) | Price (MT) |

|---|---|---|

| 2 | 5 | 150-200 |

| 5 | 10 | 250-300 |

| 10 | 20 | 400-500 |

During cutting, thickness, resistanceAnd qualitysuch elements should also be considered. These factors are critical to obtain the desired results in the final product. Moreover, Istanbulor Anatolian sideThe price ranges offered by companies in such regions may also vary regional differences. Thus, it will be useful to discuss with different companies to find the most cost -effective solution.

Profile Laser Cutting Istanbul

Since Istanbul has a wide range of industry, Profile Laser Cutting PricesIt offers a very competitive market. Especially the factories on the Anatolian side, various thicknessand provides cutting services in sizes. This provides the opportunity to obtain advantageous prices for wholesale and retail purchases.

Profile laser cutting services in Istanbul, usually steelAnd provides high quality results in the cutting of other materials. Different sizeAnd lengthCustomized cutting solutions are offered for special projects with options. In addition, in line with customer demands weightAnd diameterThe most affordable prices are calculated by calculating details such as.

Since Istanbul hosts enterprises operating in many sectors, the demand for such cutting services is constantly increasing. Because, profilelaser cuttingFor those who prefer their services, Istanbul offers a wide range of services. Businesses can contact local companies to reach high quality cutting services at the most affordable prices.