Deck Trapezi Sheet Private Prices

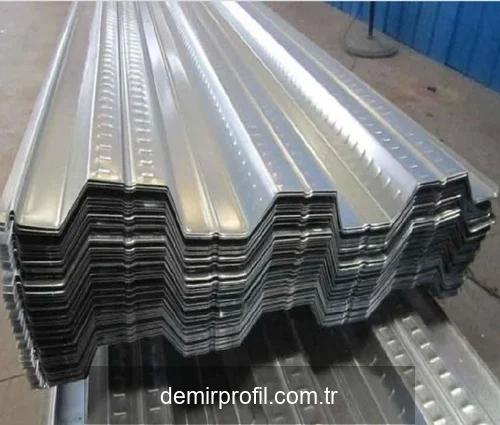

Deck Trapezi Sheet Private Prices, especially in the construction sector, it is one of the most important building materials preferred with its durability and aesthetic appearance. In regions such as Gebze, Dilovası, Istanbul and Anatolian Side, Deck Trapezoidal Sheet products are offered in accordance with every need and appeal to customers with different thickness and size options according to their usage areas. The current price table, which is determined in square meters and quantity for projects in these regions, provides convenience to customers in cost planning, while creating attractive alternatives for those looking for quality and affordable solutions.

|

Region | |

Thickness (mm) |

Price per ton TL TL |

|

Gebze |

0.50-0.70 mm |

14,500-15,000 |

|

Dilovasi |

0.50-0.70 mm |

14.200- 15.200 |

|

Istanbul |

0.50-0.70 mm |

14,800-15,800 |

|

Anatolian side |

0.50-0.70 mm |

14.600-15.600 |

The prices mentioned in this table refers to prices per tone for Deck Trapeze Sheets with 0.50 mm and 0.70 mm thick. Prices are based on sample data from certain suppliers, and it is recommended to contact local vendors for detailed information and order.

What is concrete trapeze deck sheet?

Concrete trapezoidalDeck Sac is a special metal structure often used in the construction industry. These sheets, steelor number plateMade of material and different thicknessAnd dimensionsProduced with options. The concrete trapeze deck sheets are used before pouring concrete in underground structures and the process of increasing both durability and carrying capacity.

Concrete trapeze deck sheets, usually pieceis sold through and PricesIt varies according to material quality, thickness and sizes. Especially in industrial zones such as Istanbul, Dilovası and Gebze, the supply of these products is quite common. Moreover, cutAnd transportAmong the elements that need to be considered in the operations, the weight of the sheet also has an important place. For example, the calculation of the weight in a square meter is a critical factor that affects the carrier capacity of the construction.

The concrete trapeze deck sheets provide excellent durability and long life in sub -ground applications when selected correctly. Therefore, it has become a widespread choice in construction projects. With increasing construction activities as of 2025, Deck Trapezi Sheet Private PricesIt has also been an issue that needs to be followed carefully.

Deck Trapezi Sheet Capacity

The carrying capacity of deck trapezoidal sheets is critical for the safety and durability of structures. The carrying capacity varies depending on the thickness of the sheet, the dimensions and the properties of the materials used.

The main factors affecting the carrying capacity of the deck sheets are as follows:

| Feature | Explanation |

|---|---|

| Thickness | Deck sheetThe thickness is directly effective on carrying capacity. Thicker sheets usually have a higher carrying capacity. |

| Dimensions | The dimensions of the sheet also affect the carrying capacity. Larger plates provide the load distribution better, while the carrying capacity for smaller plates may be less. |

| Material | Made of durable materials such as steel deck sheets have higher load carrying capacity. Galvanized steel sheets also offer a long -lasting option thanks to corrosion resistance. |

When calculating the carrying capacity, the floor feature to be placed in the sheet should be taken into consideration. Used on concrete floor concrete trapeziaThe sheets usually provide a better infrastructure.

For example, in regions such as Istanbul, Dilovası or Gebze, the ground condition and climatic conditions are among the issues that should be taken into consideration when building construction. Carrying capacity, usually tonor kgexpressed in terms of. The carrying capacity calculated for certain sizes and thickness combinations is of vital importance in construction projects.

In conclusion, Deck Trapezi Sheet Private PricesThe correct calculation of the transport capacity while determining will be important for both cost and safety.

Underground deck trapezoidal sheet features

Under ground deck trapezi sheetis a structural element that is frequently preferred in the construction sector. Generally steelThese sheets, which are produced from the material, have a significant transport capacity and can be used safely especially in underground structures thanks to their durability.

This trapeze floorSome features of the sheets are:

- Thickness:Under ground deck sheettheir thickness varies according to the requirements of the project. Usually there are thickness options between 0.5 mm and 2 mm.

- Weight:The weight of these sheets varies according to the selected thickness and dimensions. Weight, usually tonexpressed on the basis.

- Dimensions: Deck sheetcan be produced in different sizes. Different regions such as Istanbul, Dilovası, Gebze and Anatolian Side MTIt can be supplied in lengths.

- Durability:Under ground subcontractorSince the sheets have high durability properties, they offer safe use even under difficult conditions.

- Price:Under ground deck sheetPrices vary depending on factors such as thickness, menstruation and size. Prices are expected to increase as of 2025.

These features are under the ground deck trapezi sheetIt makes its use even more attractive and allows you to achieve high performance in your projects with the right product selection.

Deck Trapeze Sheet Widths

Deck trapezoidal sheets are widely used in the construction sector. These sheets are designed for use in various projects with different width and thickness options. Deck Trapezi Sheet Private Pricesand vary according to these widths.

The typical width of the deck trapezoidal sheets is as follows:

| Width (mm) | Application area |

|---|---|

| 600 | It is generally preferred for light structures and small projects. |

| 800 | It is widely used in medium -sized projects. |

| 1000 | It is often preferred in industrial structures and large projects. |

| 1200 | It is an ideal option for large areas. |

These width options may vary according to the needs of projects. Moreover, deck sheetThe quality of the materials used in production is also an important factor. The trapezoidal sheets produced from steel provide a long -lasting alternative by offering high durability.

Width quarries are also determined with weight and thickness. Users are suitable weightAnd thicknessBy selecting the combination, the most appropriate for the requirements deck trapezoidal sheetscan supply. Istanbul, Dilovası, Gebze and Anatolian side is very easy to supply such sheets.

In addition to different width options, annual price changes should be considered. Foreseen for the year 2025 PricesBy following, it is possible to find the most economical solutions.

What is Betonalti Deck Sac?

Concrete deck sheetis an important building element used in the construction sector, especially in floor applications. This is usually made of steel hair, the load carrying capacity is high and forms the basis of reinforced concrete structures. One of the biggest advantages of these sheets is that they can be easily transported and mounted thanks to their low weights.

Concrete deck sheetApplications are generally preferred on floors that require aggregate filling material. Such trapezeThe sheets reduce the costs of the projects and shorten the construction time thanks to their lightness features with load -bearing capability. In addition, it is frequently used in industrial zones such as Istanbul, Dilovası and Gebze.

This type of sheet, thicknessAnd weightWith the variability of such sizes, it can adapt to many different projects. One of the most important factors to consider in the selection of subcontracted subcontracting trapezoidal systems is the quality of the load and material used.

Concrete deck sheetFloors made with PricesIt varies according to the type of material used and shoulder width. Estimated for the year 2025 price, depending on both material quality and supply demand status.

| Feature | Value |

|---|---|

| Material | Steel |

| Thicknesses | 1 mm, 1.5 mm, 2 mm |

| Weight | kg/m² |

| Carrying capacity | Ton |

Concrete deck sheetSystems play a critical role for the success of construction projects. Correct use and selected piecewith PricesConsidering, it contributes to increasing the cost effectiveness of the project.

Concrete deck trapezia weights

Weights of concrete deck trapezes, used steelIt varies depending on the plate thickness and sizes. In general, the weights of these trapezes, square meters ( MTkilograms per head ( kgis calculated as). Here is a table that shows the weights of concrete trapezes with different thickness and sizes:

| Thickness (mm) | Size (M) | Weight (kg/m²) |

|---|---|---|

| 0.75 | 1.00 | 7.85 |

| 1.00 | 1.00 | 10.45 |

| 1.25 | 1.00 | 13.1 |

| 1.50 | 1.00 | 15.75 |

These weights, concrete trapeziaThey are important factors to consider in their use. Especially Istanbul, GebzeAnd DilovasiTo be used in construction projects in such regions deck trapezi sheetCalculation of these weights with menstrual prices is of great importance for transport and assembly operations. It is possible to develop appropriate solutions by considering the weights in the selection of materials and cost calculations.

Deck Trapeze thicknesses

Deck Trapezoidal Sheets are produced in various thicknesses in accordance with different construction projects. These thicknesses directly affect the durability of the sheet and the load capacity it can carry. The deck trapezoidal thickness usually usually used contains sizes ranging from 0.75 mm to 1.5 mm.

| Thickness (mm) | Weight (kg/m²) |

|---|---|

| 0.75 | 7,50 |

| 1.00 | 10,00 |

| 1.25 | 12,50 |

| 1.50 | 15,00 |

Deck trapezi sheet Menstrual Prices, it varies according to thickness and sizes. For example, the cost of thicker sheets is usually higher. In these areas such as Istanbul, Dilovası, Gebze and Anatolian Side, this thickness and sizes PricesIt is possible to find.

Finally, suitable for the project deck trapeziaIt is vital to consider the thickness, weight and carrying capacity when choosing. The right choice will ensure that the project is long -lasting and the cost of the cost is to create an effective structure.

Galvanized Deck Usage Areas

Galvanized Deck Sac has a wide usage area in the construction sector. It is generally preferred in roofing, flooring and various structural applications. Especially Deck Trapezi Sheet Private PricesWith cost -effective solutions with, increases the popularity of this product.

The most prominent usage areas of the galvanized deck sheet are as follows:

- Roofing:Thanks to its durable structure, it provides optimal protection against weather conditions.

- Floor Floors:Under ground in housing and industrial buildings concrete trapeziaused as.

- Modular Structures:It contributes to fast construction processes by offering easy assembly.

- Industrial Facilities:It is an ideal choice with heavy load carrying capacity.

- Workshop and warehouse areas:Thanks to its high durability, it is often used in storage areas.

- Agricultural Structures:It offers an economic and solid option in agricultural projects such as greenhouse.

For these reasons, galvanized Deck Sac finds its place as an important material in construction projects both in terms of durability and economic terms. With the developing technology galvanized deckThe quality of the varieties increases, which expands the usage areas.

What are the differences of 38/151 and 60/940 deck trapezoidal differences?

Deck trapezoidal sheets, such as thickness, width and carrying capacity, may vary according to the requirements of the structure. Especially, 38/151And 60/940Deck trapezes with dimensions have certain differences. These differences directly affect the reasons for preferring according to use areas and structure types.

| Feature | 38/151 deck trapezoidal | 60/940 deck trapezoidal |

|---|---|---|

| Width | 38 mm | 60 mm |

| Height | 151 mm | 940 mm |

| Weight (ton/m²) | kglighter than the genre | kgheavily |

| Uses | Light structures | Heavy structures and industrial areas |

Deck Trapezi Sheet Private PricesThere are significant differences between these two sizes. Generally, 38/151While offering a more economical option, 60/940It can be a long -lasting investment by providing more transport capacity and durability.

Finally, both types trapezeThe recommended usage areas for sheet vary depending on the needs of your project. Also, according to regions (eg, for example Istanbul, Dilovası, Gebze, And Anatolian side) Price and supply conditions are also an important factor.

Frequently asked questions

What is Deck Trapezia Sheet?

Deck Trapezoidal Sheet is metal sheets in the form of trapezes, usually used in the construction industry. These plates are preferred for waterproofing and aesthetic appearance as well as providing structural support.

Deck Trapezia Sheet Prices What Varily Do?

Deck trapezoidal sheet prices vary depending on the thickness of the sheet, dimensions, material type and production technology. In addition, market conditions and supply chain are among the factors affecting prices.

What should I pay attention to when buying the deck trapeze sheet?

When buying the deck trapeze sheet, you must first determine the dimensions and thickness you need, choose a reliable supplier and check the quality of the material.

How to install Deck Trapezia Sheet?

The deck trapezoidal sheet assembly is usually done by screws or welding methods. During the installation, attention should be paid to ensure smoothness during the placement of sheets and to direct the water flow.

Where to use deck trapeze sheet?

Deck Trapetes has a wide range of uses in sheet, roofing, warehouse construction, industrial buildings, agricultural structures and various construction projects.

What are the advantages of the deck trapezoidal sheet?

Deck Trapezoidal Sheets offer many advantages with their light structures, high durability and aesthetic appearance. It is also an important plus that they can be easily assembled and long -lasting.

What type of material should I choose when choosing Deck Trapezia Sheet?

When choosing deck trapezoidal sheet, it is important to choose resistant and stainless materials that are resistant to environmental effects. Options such as galvanized steel or aluminum can increase durability.