Stainless Steel Sheet Private Prices

Stainless Sheet Private Pricesvaries depending on many factors. Primarily, used stainless steelQuality and dimensionsIt is one of the most important elements affecting prices. For example, 316And 316LIt has high corrosive resistance like steelTypes generally have higher price ranges. Likewise, thicknessAnd weightPhysical features such as also affect pricing.

| Stainless sheet quality | Price range (kg) |

|---|---|

| 201 | 20-25 TL |

| 304 | 30-35 TL |

| 316 | 40-45 TL |

| 430 | 25-30 TL |

These prices are on Istanbul, Dilovası, Gebze and Anatolian Side stainless sheetIt varies according to suppliers. TonWhile purchases can usually be made at lower unit prices, piecePrices may be higher in purchases. Therefore, it would make sense to consider making bulk purchases for large projects.

Stainless steel sheet prices are an issue that needs to be followed regularly as it may show fluctuations in the market. Moreover, number plateIn addition to its features, labor and shipping costs are among the factors that affect the total cost.

Stainless sheet quality

Stainless hairtheir quality varies according to their usage areas and maintenance requirements. These quality, stainless steelIt is determined depending on the alloy elements contained in the s, so that each quality has certain physical and chemical properties. Below is a brief description of the most common stainless sheet quality.

| Quality | Explanation | Application area |

|---|---|---|

| 201 | Suitable for hot environments with high mechanical properties. | General uses, automotive industry. |

| 304 | It has high corrosion resistance, versatile. | Food processing, chemical industry. |

| 316 | It is the best option for marine environments, has high salt resistance. | Marine equipment, medical tools. |

| 430 | It has a semi -bright surface properties and has moderate resistance to oxidation. | Household items, interior design of cars. |

| 321 | Resistant to high temperatures, reduces the risk of corrosion. | Aircraft parts, high temperature environments. |

| 316L | It provides welding with low carbon content. | Chemical industry, food processing. |

This your qualityEach has a specific price range and these prices may vary depending on material supply and market conditions. Especially Stainless Sheet Private PricesWhen getting information about it, it is important to consider the quality and purpose of use.

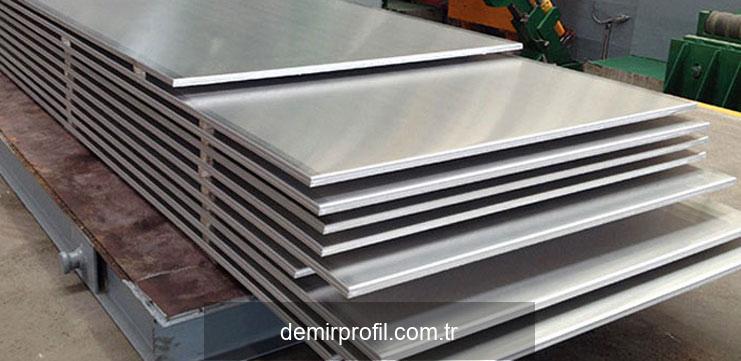

Stainless Steel Features

Stainless steel is a very preferred material used in various industrial and commercial applications and is very preferred in terms of durability and aesthetics. The most important of this material FeaturesThere are corrosion resistance, wear resistance and resistance to high temperatures. Stainless steel can be customized with different alloys and surface operations, which makes it versatile.

Mechanical properties of stainless steels, so durability, stress resistanceAnd prolongation percentageIt plays an important role depending on the application area. For example, 316And 316LTheir quality is ideal for use in sea water and chemical environments, so it is widely preferred in the food processing industry, petrochemical and utim industry.

In addition, stainless steels are easy to processable, cutting, drilling, And formingfacilitates such operations. This feature covers a large area, especially in the construction and automotive sector. Stainless steel materials, pieceWhen taken as, varies according to the sector Pricestogether with, especially in regions such as Istanbul, Gebze and Dilovası.

The aesthetic diversity of stainless steels is also very important. ShinyAnd matSurfaces are preferred for different applications, which adapts to aesthetic expectations in design and architectural projects.

Stainless steel sheet plate weights

Stainless steel sheet plate weight varies depending on the thickness and size of the sheet. When making weight calculations, your sheet thickness, dimensionsAnd intensityfactors such as. Generally, the density of stainless steel sheets is around 7.9 g/cm³. This information plays an important role in weight calculations.

| Thickness (mm) | Size (m²) | Weight (kg) |

|---|---|---|

| 1 | 1 x 2 | 15.8 |

| 2 | 1 x 2 | 31.6 |

| 3 | 1 x 2 | 47.4 |

| 4 | 1 x 2 | 63.2 |

| 5 | 1 x 2 | 79.0 |

| 6 | 1 x 2 | 94.8 |

The table above, stainless steel sheet plates of different thickness and sizes weightshows. For example, a stainless sheet plate with a thickness of 1 mm is 15.8 kg of 1 x 2 meters. In this way, appropriate according to need stainless sheetquantity and Pricescomputable.

Since various quality (such as 304, 316, 430) are available in the market, these sections tonweights are also an important factor. Especially in construction and industrial applications, weight and durability in the use of stainless steel sheet are important requirements. Hence, correct priceFor analysis, plate weights should be calculated in detail.

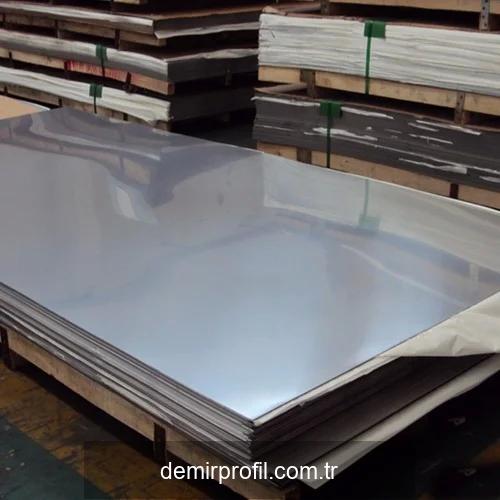

Stainless steel surface types

Stainless steel sheet can offer various aesthetic and technical specifications with different surface types. These surface types vary according to the usage area and needs of the product. Here are the most widely used stainless steel surface types:

- Bright surface: It is the surface that creates a reflection effect with high smoothness. It is generally used for decorative purposes and is available in 430 %, 316 %.

- Matte finish: It is the surface that offers a less reflective feature, offering a rough appearance. It is suitable for intensive usage areas and is preferred in stainless steels passing through heat treatment.

- Brushed surface: This species, which is a type of matte surface, is obtained by a special brushing process. It is a preferred surface in terms of both aesthetics and durability.

- Rustin Surface: It has a layer of coating on the stainless steel sheet that provides natural protection against corrosion. This surface type is generally used in outdoor applications.

Selection of surface types, stainless steel sheet Menstrual PricesIt may also be effective on it. Since the quality of the surface is reflected in the value of the processing cost and the value of the final product, the right surface selection is important for cost effectiveness. Especially in industrial zones such as Istanbul, Dilovası and Gebze, taking into account such elections Price rangesvaries.

Stainless steel surface types play an important role not only in aesthetics, but also in terms of functionality. Therefore, making surface selection appropriate to need will provide an advantage in terms of both performance and cost.

Stainless sheet quality

Stainless steel is widely used in the industry with its different quality. Each quality has its own characteristics and application areas. Here are the most common stainless sheet quality:

| Quality | Features | Uses | Price range (ton) |

|---|---|---|---|

| 201 | Low cost, corrosion resistance medium | Food processing, decorative applications | Xx.xxx – xx.xxx |

| 304 | High corrosion resistance, long -lasting | In the food industry, water tanks, chemicals | Xx.xxx – xx.xxx |

| 304L | More suitable for the source with lower carbon content | Chemical Industry, Food and Pharmaceutical Industry | Xx.xxx – xx.xxx |

| 316 | High corrosion resistance, resistant to saline | Sea and petrochemical industry | Xx.xxx – xx.xxx |

| 316L | Low carbon, high corrosive strength | Pharmaceutical Industry, Food Processing Equipment | Xx.xxx – xx.xxx |

| 430 | Magnetic structure, moderate corrosion resistance | Flooring, household items | Xx.xxx – xx.xxx |

These quality varies in terms of stainless sheet price prices. Stainless sheetMenstrual prices may vary depending on the market and the supplier. Especially Istanbul, Gebze, DilovasiIt is among the factors affecting competition and local demand prices in such regions. Stainless sheet pieceIn addition to prices, tonAnd kgPricing on the basis is also common in the sector. The characteristics and costs of the quality are among the important elements when choosing.

201, 304, 304L, 316, 316l, 309, 316ti, 321, 430 stainless sheet quality

Some of the most common ones of the stainless sheet quality are 201, 304, 304L, 316, 316L, 309, 316ti, 321 and 430. Each quality has its own characteristics and usage areas. Below are short descriptions and basic features of these quality:

| Quality | Explanation | Features |

|---|---|---|

| 201 | Stainless sheet is generally preferred for lower cost alternatives. | Low corrosion resistance, high cold forming capability. |

| 304 | The most common stainless steel quality is a wide application area. | High corrosion resistance, good mechanical properties. |

| 304L | It has the ability to make better welding due to its low carbon content. | Corrosion resistance is better than 304, the probability of carbide precipitation after welding is low. |

| 316 | It is used in chemical medium and sea environments, has high corrosion resistance. | Excellent corrosion resistance, especially against chloride. |

| 316L | The welding capability has been increased with low carbon content. | Corrosion resistance is high, the probability of carbide precipitation after welding is very low. |

| 309 | It is ideal for high temperature applications. | High temperature resistance and oxidation resistance. |

| 316ti | Corrosion resistance was increased with the titanium contribution. | High temperature resistance, corrosion resistance level is high. |

| 321 | Stabilized stainless steel quality with titanium. | Suitable for high temperature applications. |

| 430 | Ferritic type is stainless steel quality, usually used for decorative purposes. | The stain feature is good, but not as good as 304 and 316. |

Each of these quality is customized for different industrial and commercial applications. Especially Stainless Sheet Private PricesIn determining, it is of great importance to know and make accurate purchase. Another factor to consider in quality selection is the use of use; For example, 304 quality in food processing facilities and 316 quality are preferred in chemical plants.

Stainless steel surface cleaning

Cleaning of stainless steel surfaces is very important for both aesthetic appearance and the durability of the material. Stainless sheetStructures are used extensively especially in industrial areas, so regular cleaning processes ensure that this structure is long -lasting.

Methods and materials to be applied for surface cleaning, stainless steelIt may vary depending on quality and surface type. In general, the following steps should be followed for stainless steel surface cleaning procedures:

- Selection of Chemical Cleaning Products:Steel cleaning products usually have an acidic or alkali structure. In the selection of these products, the type and contamination rate of the surface should be taken into consideration.

- Pre -cleaning of the surface:The surface must be purified from dust and dirt before cleaning. For this, it is sufficient to wipe the surface using a damp cloth.

- What to consider during cleaning:Sanding or abrasive substance use should be avoided during the cleaning process. This may cause scratches on the surface.

- Rinse:After chemical products are applied, the surface should be rinsed with plenty of water. Water residues should be completely removed as it can leave stains on the surface.

- Establishment:It is recommended to wipe with a microfiber cloth for the surface to dry completely after cleaning.

Stainless steelThe cleanliness of the surfaces is important both in functionality and aesthetics. With appropriate cleaning methods and products, the life of these surfaces can be increased, and the appearance can always remain bright as the first day.

Stainless Steel Differences Between Bright Surface and Mattal Surface

Stainless steels are widely used in industrial applications. The surface types of these materials vary significant differences in terms of aesthetic and functional properties. The bright surface and matt surface, which are two basic surface types, offer different advantages in various fields.

Bright surface

Bright stainless steelProvides a high aesthetic appearance by effectively reflecting the light. This surface type is generally preferred for modern and stylish designs. It has widespread use especially in kitchen utensils, decorative products and automotive sector. Although the bright surface requires maintenance, it is easy to clean and shows the stains less on the surface.

Matte finish

Matte Stainless SteelIt has a less bright appearance and is generally preferred in industrial applications. The matte surface draws less attention by reducing reflection and is more effective in hiding fingerprints on it. In addition, matte surfaces usually require less maintenance and durable.

Election Criteria

The following criteria should be considered when choosing:

- Aesthetic needs: Bright or matte surface preference should be made according to the design of the project.

- Application area: Matte surface for industrial use is more suitable for decorative purposes and bright surface is more suitable.

- Maintenance and Cleaning: Bright surfaces should be cleaned more frequently; Matt surfaces require less attention.

Stainless Sheet Private PricesThe surface types that affect it should be selected according to the requirements of your project and aesthetic preferences. Each surface type comes with its own advantages and disadvantages; Therefore, it is important to make the right choice.

Which is the best quality stainless

Stainless steel, with different quality and use in the industry and construction sector is of great importance. However, which stainless steel is the highest quality, varies according to the areas and conditions to be used. Among the most widely used stainless steel quality 304, 316And 430It comes to the fore.

| Stainless steel quality | Features | Uses |

|---|---|---|

| 304 | Good corrosion resistance, heat stability | Food industry, kitchen utensils |

| 316 | High resistance to sea water | Sea structures, chemical operations |

| 430 | Lower corrosion resistance, cheap cost | Indoor applications, decorative objects |

316Its quality is known for its resistance to challenging conditions, especially in marine environments, and is therefore an ideal choice for those looking for high quality stainless steel. On the other hand, 304Its quality is suitable for all kinds of general use and has a good corrosion resistance. If you are looking for an optimum selection considering the price/performance ratio, 430You can choose quality, but this quality has lower corrosion resistance than others.

As a result, the best quality stainless steel selection depends on the needs of your project and your budget. Each of the different quality has the original advantages and knowing them allows you to choose the right choice. Remember, the best quality option may not always be the most expensive; It is also very important to adapt to the needs of the area you will invest.

Frequently asked questions

What is stainless sheet?

Stainless sheet is a type of steel with at least 10.5 %chrome and thus gaining stainless properties.

What are the varieties of stainless sheets?

Stainless sheets are usually divided into three main categories: Austenitic, ferritic and martensitic species.

What are the factors affecting stainless sheet prices?

The main factors affecting stainless sheet prices are the material quality, sheet thickness, market demand and exchange rates.

What should we pay attention to when buying stainless sheets?

When buying stainless sheet, the standards, dimensions, quality and reliability of the supplier should be considered.

Where is stainless sheet used?

Stainless sheet is used in a wide range from architecture to kitchenware, automotive to medical equipment.

How to determine stainless sheet price prices?

Stainless sheet prices are determined according to market conditions, order quantity and pricing policies of the supplier.

What is the best time to get stainless sheet?

In general, regardless of seasonal fluctuations, prices are more likely to be more affordable when the market is stable.